For over 15 years, Bludeek has specialized in precision machining for industries such as optical imaging, fluid control, superconducting technology, and aerospace. Our digitalized production system ensures full process monitoring, traceability, and real-time online support — from quotation and ordering to progress tracking and quality file access. We are trusted by customers who demand the highest standards of quality and accountability.

Our 65-member engineering team brings deep expertise in metals and engineering plastics, with proven strengths in complex geometries, thin-walled cavities, and custom structural parts. By applying advanced 3D simulation and DFM analysis before production, we minimize risks, control costs, and deliver efficient, reliable results.

Capability of Bludeek

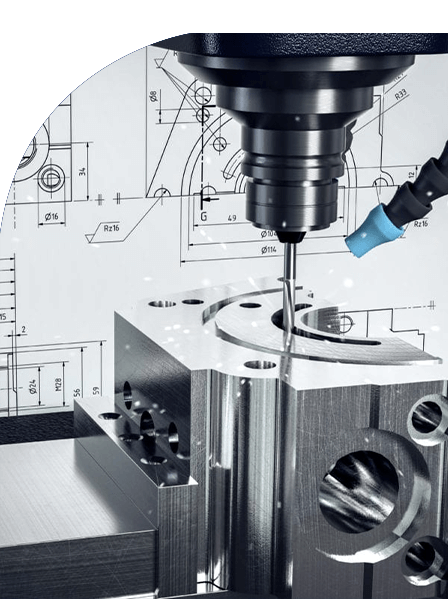

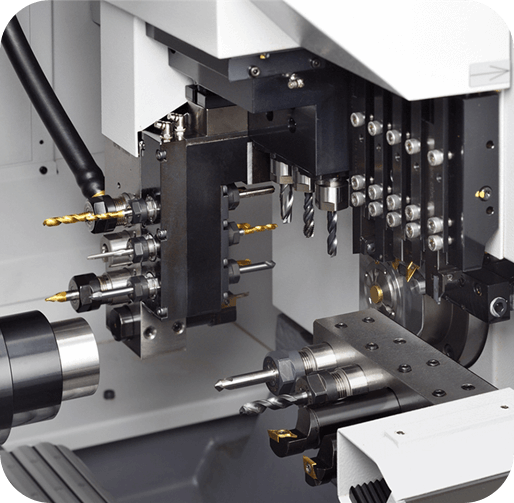

CNC Milling

At Bludeek, we operate three advanced facilities equipped with over 100 CNC machines, offering 3-, 4-, and 5-axis as well as horizontal milling services. Whether your parts are simple or highly complex, we deliver precision machining with efficiency you can rely on. We back every order with fast turnaround times—shipping in as little as 5 days—together with 100% quality inspection, detailed 3D CMM reports, digital model scans, and a no-risk guarantee with free replacements for any defective parts.

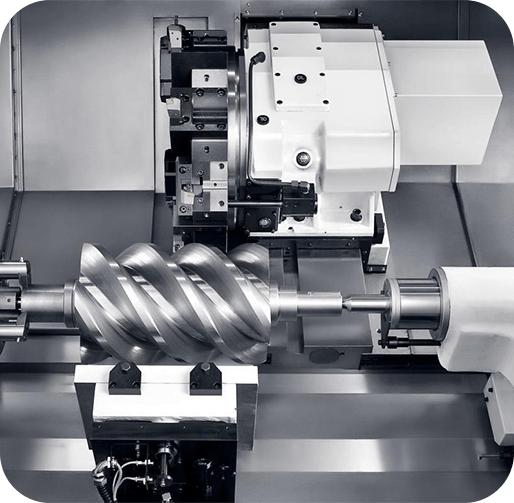

CNC Turning

At Bludeek, we produce custom parts under rigorous manufacturing standards, ensuring every component and process meets our strict internal benchmarks. Each order comes with a detailed inspection report for full transparency and quality assurance. We promise fast delivery in as little as 5 days, 100% outgoing quality control, precise 3D CMM measurement reports, digital model comparison through 3D scanning, and a worry-free guarantee with free replacement of any defective products.

Swiss Turning

At Bludeek, we specialize in Swiss turning for small, high-precision components. Using advanced 7-axis Swiss turning centers, we can produce complex geometries with ultra-precision and hold tolerances as tight as ±0.001 mm. Each part is manufactured under strict quality standards to meet the demands of critical applications. We offer delivery in as little as 5 days, 100% outgoing quality control, and 3D scanning with digital model comparison to guarantee accuracy and consistency for every order.

Partner: Fladic

End-to-End Project Solutions